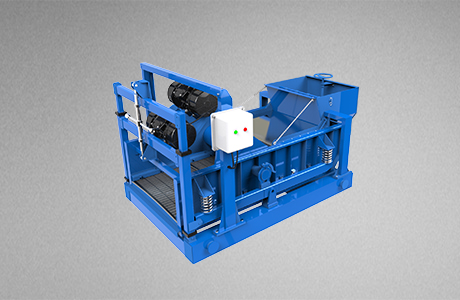

Drilling Fluids Shale Shaker

Drilling Fluids Shale Shaker that all the industries that operate in natural and non-renewable sources of energy need a Shale Shaker. They can be widely used in oil and gas industries. Drilling and Mining Industries are also in dire need of Shale Shakers. Another industry that makes use of Shale Shakers is a coal cleaning industry.

Without the help of Shale Shakers, all these industries could face trouble and huge expenditure incurred in procuring the oil and gases through the tedious and time-consuming processes. The very first step of drilling begins with a Shale Shaker. The machines operated to separate the solids from the liquid.

The fluids, which are otherwise disposed and considered of no use at all, are wonderful lubricants and cooling agents for the Shale Shaker .

The only negative aspect of the fluids is chemicals mixed inside them that would be present in water and oil based solutions irrespective of their unique qualities.

It is a boon for industries of 21st century. Shale Shakers are highly effective, environment friendly, cost effective, and error-free. However, they need only specialized personnel and professionals to work properly.

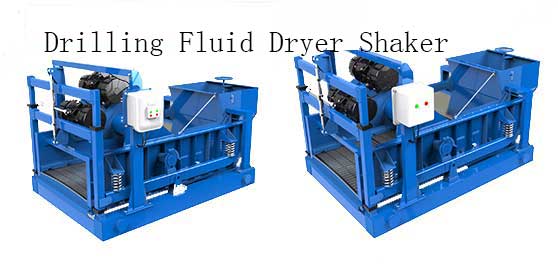

The functions of the drilling fluids include;

1- It transports cutting to the surface.

2- It minimizes formation damage to an enormous extent.

3- It acts as a cooling force and a source of lubrication.

4- It prevents well-control issues.

5- It provides relevant information about the source.

6- It is easy on environment and does not emit harmful chemicals into the atmosphere.

7- It minimizes the risk to drilling equipment.

8- They work like a boon in high temperatures and hotter climates.

9- It can be re-used repeatedly and has longevity.

10- It reduces the chances of machine failures to a great extent.

Drilling Fluids can be hazardous and handling them requires specialized personnel who can operate and test it daily and continuously monitor it for flaws and errors.