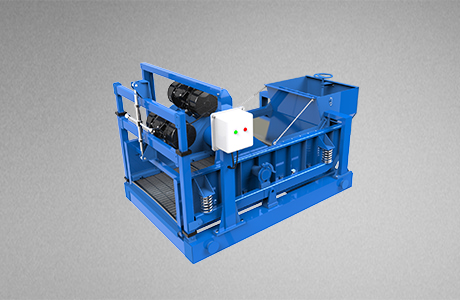

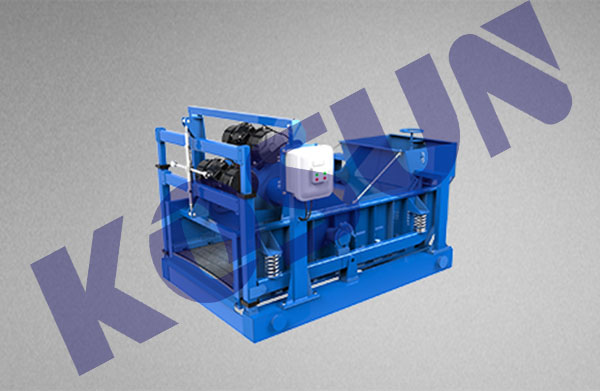

As the 1st part of mud utilization,drilling fluids shale shakers are often expeditiously have an effect on the improvement method. KOSUN shale shakers with shear pump is animated by G force, which might be adjusted accruing to the various scenario. In general, the GHB force are often additional to seven.4G. So, shale shaker screen will change the force in accordance with their totally different things.

KOSUN field shale shakers is nice at the significant solid hundreds and high process capability. Every time, the device permits bearing lots of solids. With an explicit amount, KOSUN drilling fluids shale shakers might have a decent performance to separate and clean. Besides, mud gun options the only deck. The AWD angle is allowed to be adjusted from -1°to 5°. So, mud gun might create a decent adjustment thus on transfer, separate and clean mud.

KOSUN shale shakers for lubricator system has not solely technical options, however additionally some advantages. for instance, the decanter centrifuge instrumentality has low energy consumption, Drilling Waste Management high production and automatic performance. decanter centrifuge is most significantly, field shale shakers offered by KOSUN shear pump options straightforward structure, however DWM Solids Control’s excellent compact style, that is definitely to be maintained. Contact us for additional data concerning sedimentary rock shaker.

As a necessary part of solids management instrumentality, sedimentary rock shaker plays a very important role within the field.It’s the primary stage of solids control system. without doubt, lubricator shale shaker screen is crucial. KOSUN solid control system has reliable field drilling shale shaker screen, that has many distinctive options in Dwm control.

Kosun- Solids Control Company/ Drilling Waste Management Company