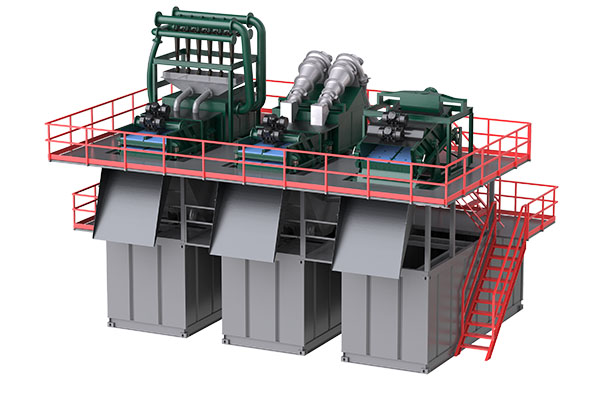

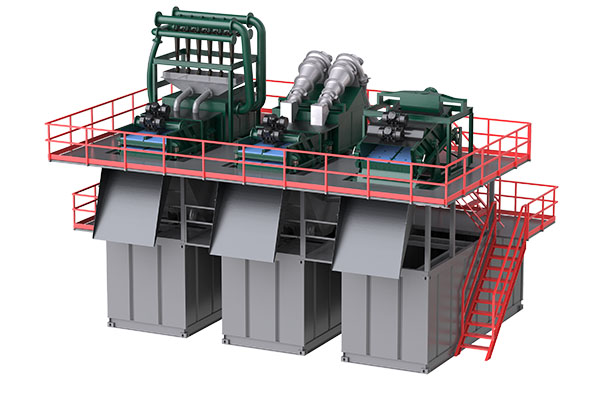

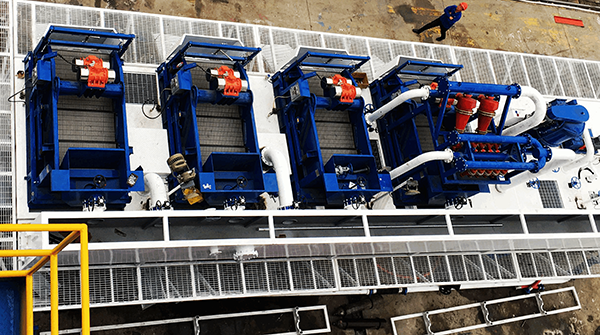

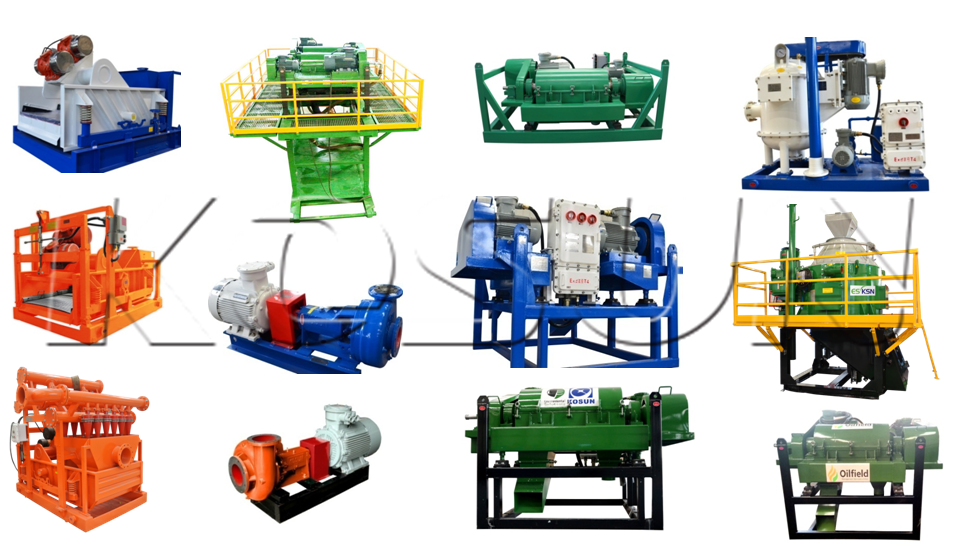

Recently, batches of shale shakers and desanders equipment produced by KOSUN were sent to Kazakhstan to be used in a well-known drilling engineering service company’s oil exploration project in Kazakhstan. It is mainly used to remove harmful Solid Phase drilling fluids during drilling. The provision of this equipment is the tenth year that the company has continued to use KOSUN products in foreign projects. The continuous repurchase by customers is the biggest recognition of KOSUN products!

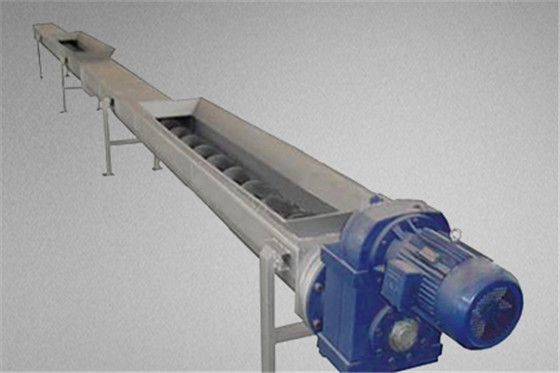

As the primary solids control equipment in the drilling fluid purification system, the shale shaker is mainly used to separate the large particles of drill cuttings contained in the drilling fluid. Desander is a secondary solids control equipment for processing drilling mud. It can separate solid particles between 45 and 74 microns. According to the different processing capacity , 1, 2 or 3 sets of 10″ or 12″ can be flexibly selected. The desander is mainly composed of shale shaker, cyclone, a branch manifold, and an electric control system, and is used to separate solid particles that cannot be separated by the shale shaker.

KOSUN is a professional manufacturer of mud solids control equipment and drilling waste treatment systems integrating product development, production and sales. The products are widely used in oil and natural gas drilling, coalbed methane drilling, geothermal drilling, trenchless horizontal directional crossing, pipe jacking, shield tunneling, piling and other projects, tailings treatment, river dredging and other fields. If you want more information, please contact us!

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com