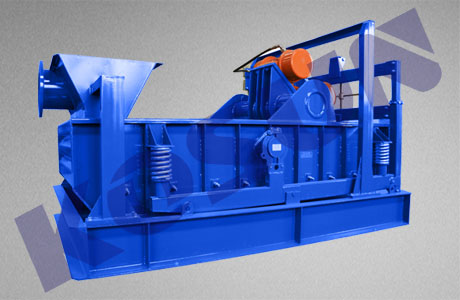

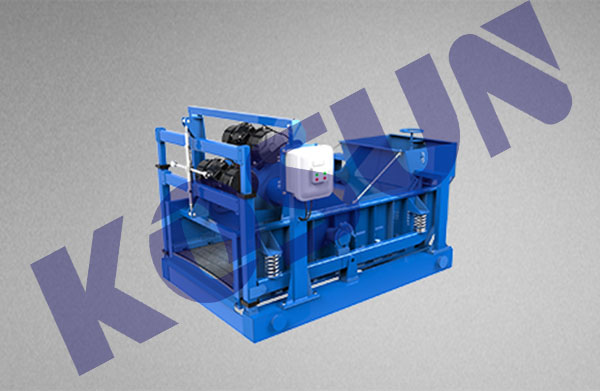

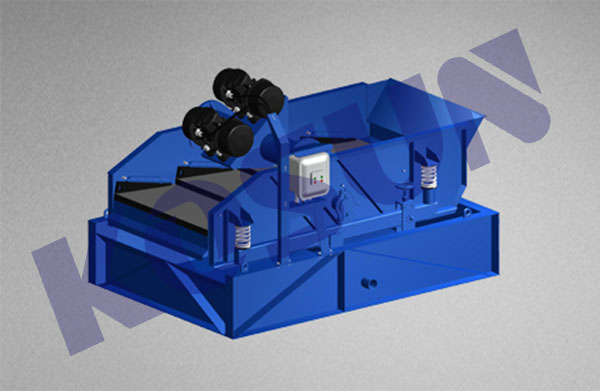

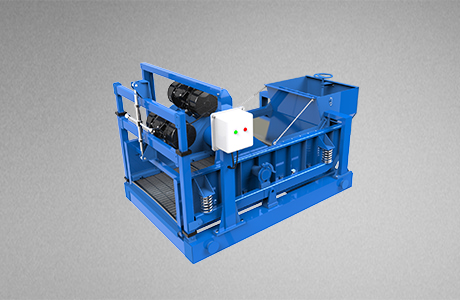

Do you know the Double Deck Drilling Fluids Shale Shaker ? Now Let’s talk the avantages and disadvantage of it.

Advantages of Double Deck Drilling Fluids Shale Shaker:

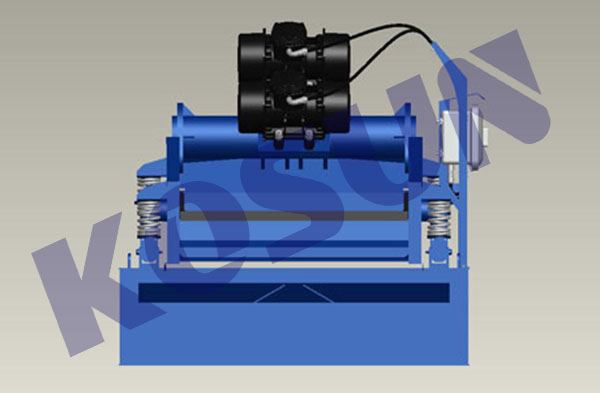

- For the same API size and the same area bottom shale shaker screen,double deck shale shaker can treat a bigger capacity. The wide-meshed shaker screen on top deck can separate most big size solids before the mud enter into the bottom deck. It greatly reduce the load of bottom shale shaker screen.

- For the same API size and the same screen area shaker screen,double deck shale shaker can separate the drilling mud or drilling cuttings more dryer. As there are 2 times shale shaker separation.

Disadvantages of Double Deck Drilling Fluids Shale Shaker:

The double deck shale shaker have advantages of bigger advantage and dryer separation result, but it has some difficult to change shale shaker screen. And the cost of replacement shaker screen also higher, as there are 5 each shaker screen for a shale shaker.

Shale shaker for solids control are devices that remove drill cuttings from the drilling fluid while circulating and drilling. There are many different designs and research into the best design is constantly ongoing since solids control is vital in keeping down costs associated with the drilling fluid. The basic design consists of large, flat sheets of wire mesh screens or sieves of various mesh sizes that shakes or vibrates the drill cuttings, commonly shale shaker, across and off of the screens as the drilling fluid flows through them and back into the drilling fluids processing system, often called a mud system. This separates the drill cuttings, often called solids, from the drilling fluid so that it can be recirculated back down the well bore.

In oilfield industry, linear motion shale shaker are widely used for drilling mud solids control of oil gas well drilling for rig.

Kosun- China Solids Control Leader&Drilling Waste MangementExpert