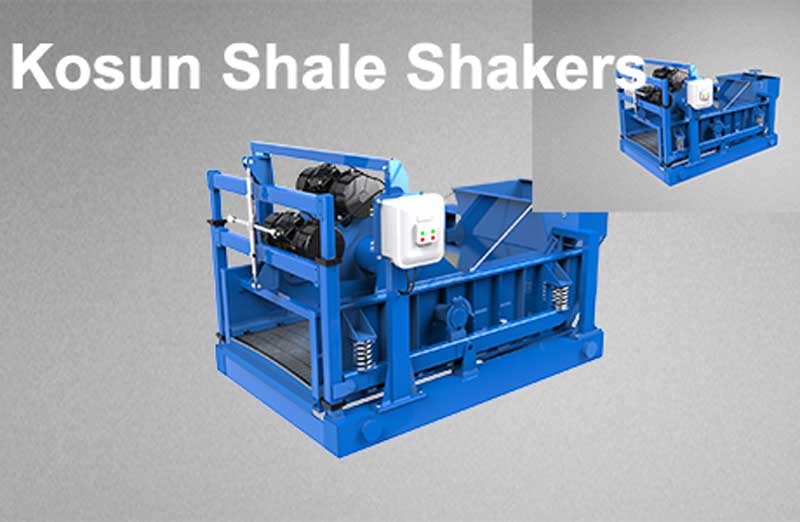

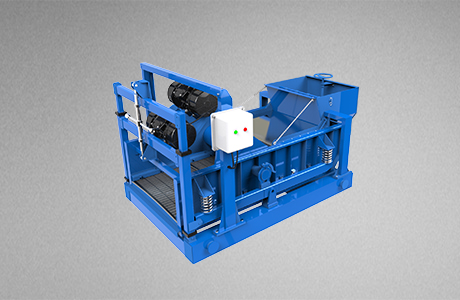

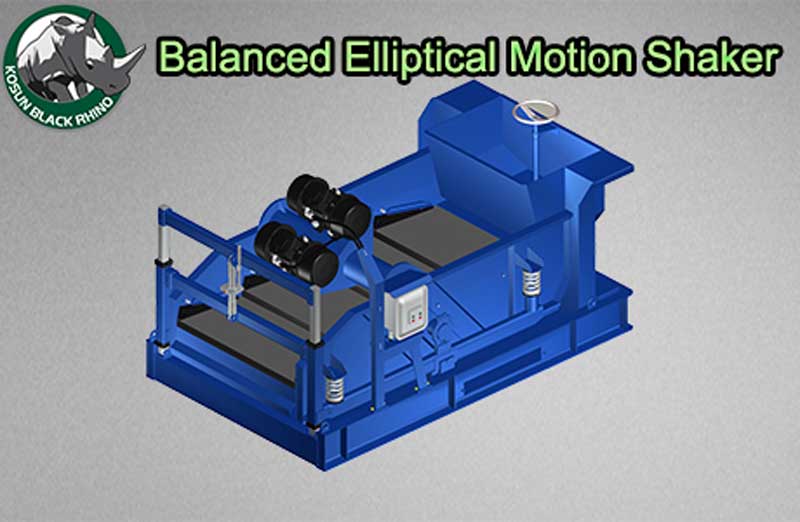

Balanced Elliptical Motion Shaker

Balanced Elliptical Motion Shaker is a key component of the solid control equipment for the drilling industry. Drilling operations use drilling techniques to penetrate deep into the surface to achieve fossil fuels, and in this quest, the mudstone machine first needs to be sampled to determine the depth and quality of the rock it penetrates. In the oil field excavation, assuming that the offshore site, the drilling will be completed with the help of the rig.

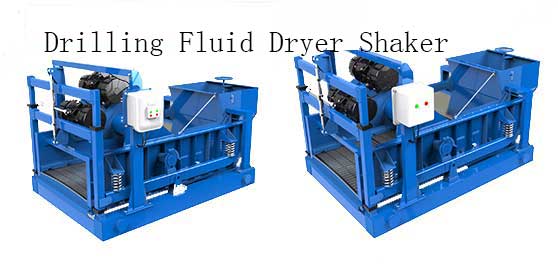

The drill bit itself will carry cuttings, which are basically shredded with drilling mud. The mud collector will extract these shavings from the drill for further analysis. As mentioned earlier in the article, the drilling fluid is very expensive, so the operator must recover the drilling fluid from the drilling waste . To this end, the use of various solid control devices, where the shale oscillator is the most important.

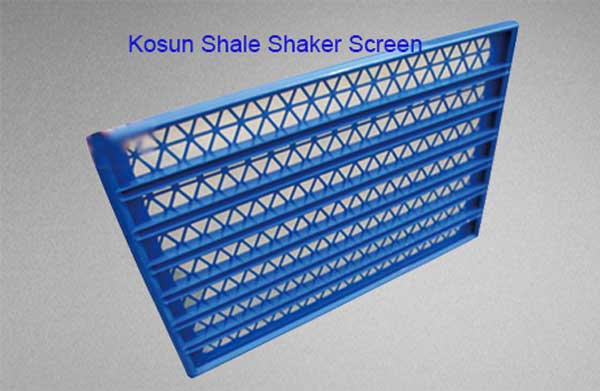

The vibrating screen with a vibrating screen helps to separate the cuttings from the drilling fluid and direct the separated drilling fluid to a separate container for further processing and handling. The dried solids, i.e., the drilling chips, are transported to a separate container for further processing and disposal.

A very important factor in solid control systems is its contribution to environmental balance. If the efficiency of the solid control system is not high enough, the cuttings are likely to carry some drilling fluids containing chemical substances that may be harmful to the environment and cause contamination of the soil or groundwater. For environmental reasons, the drilling industry follows the strict rules for drilling waste treatment .

All in all, the main function of the shale shaker is to filter the drilling waste through an effective shaker screen shield, thus contributing to the overall drilling operations and the economy of environmental precautions.