Hi-G Drying Shaker is a kind of equipment of drilling waste management system, and is used to separate drilling fluid from cuttings treated by solids control equipment.

It features in two advantages:

1.It reduces total cuttings discharge amount, discharge cost and environmental pollution;

2.The recovered drilling fluid can be recycled, which reduces the cost of drilling fluid.

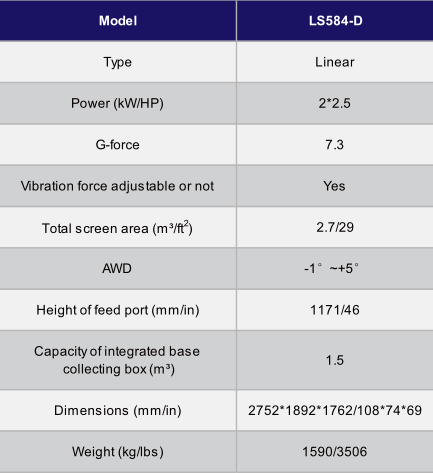

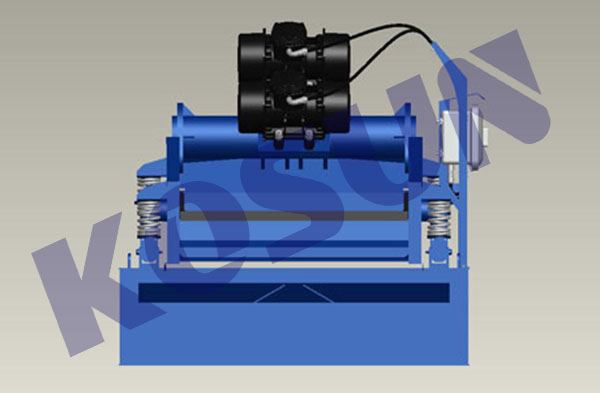

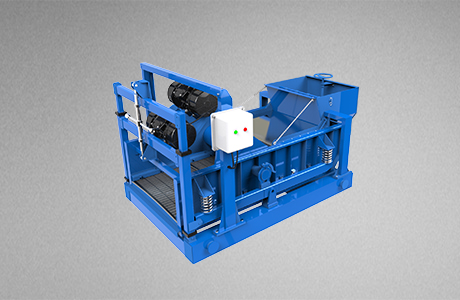

KOSUN LS584-D Hi-G Drying Shaker is a high frequency linear-motion vibrating screen machine, equipped with four screen panels and two vibrating motors, and offering a choice of manually adjusting screen frame angle while drilling (AWD). When LS584-D Hi-G Drying Shaker works, the screen frame angle can be adjusted from -1° to +5° by dint of its structural design innovation.

LS584-D Hi-G Drying Shaker can separate drilling fluid from cuttings efficiently. Fix vibrating motors onto the screen frame with a high-strength supporting seat, and position them on the screen box, and the positioning in this way can make vibrating motors directly exert G-forces on screens. The isolation mounts can protect the bedframe from vibration effect of the screen frame. Cuttings are fed into a hopper at the tail of screen box of LS584-D dryer by a conveying device.

Field-proven tensioning system is of stable performance and reliable structure. It takes less than two minutes for a person to install or remove one screen using special tools.

Kosun- China Solids Control Leader&Drilling Waste MangementExpert

Drying Shaker, dryer Shaker for Sale

KOSUN Drying Shaker,dryer Shaker is used to recover the mud from drilling cuttings,so as to reduce the liquid/oil content drilling cuttings to as low as about 10%(w/w) and recover part of the drilling mud,so that the drilling cost can be reduced and the drilling waste volume can be cut down,for the purpose of reducing environmental pollution.The Hi-G Drying Shaker,dryer Shaker suitable for both of WBM and OBM.

Features of Drying Shaker, dryer Shaker:

- High G-force vibration intensity (adjustable as per working conditions);

- Make drilling cuttings more dryer;

- Weir type feed box is more applicable to on-site process;

- Fast drilling cuttings conveying speed and high handling capacity;

- Screen frame tilt angle can be adjusted from -1° to 5°;

- Rapid screen tensioning system ensures easy screen replacement.

Advantages of Drying Shaker, dryer Shaker:

-Low maintenance dryer reduces operational costs.

-Wedgelok system allows for quick screen changes.

-Centrifugal pump and spray bar unit built into the fluid recovery tank.

-Single shaker unit is mounted in a four sided shale bin.

-Dual Shaker unit is skid mounted for easy, cost effective transport.

-Includes an auto-pump feature to prevent potential spills.

KOSUN’s solids control and waste management solutions can provide a closed-loop, zero discharge system to meet all your needs when it comes to location, budget, safety and environmental requirements. KOSUN offers premium linear motion drying shaker to ensure a fast and efficient turnaround time on your fluid recovery process. The linear motion drying shakers are a multi-functional drilling fluid cleaner that is equipped to handle varying drilling fluid viscosities and remove solids from your drilling fluid. It is designed with a high g-force and pretensioned screens to optimize the flow of drilling fluids. It provides a cleaner reclaimed fluid that can be utilized back into the drilling fluid program.

Kosun- Solids Control Company/ Drilling Waste Management Company

Drying Shaker for Sale 5 Percent Off by Kosun

Drying Shaker for Sale

Drying shaker for sale by Kosun has attracted clients at home and abroad, and the drying shaker for sale this time mainly used in geographical engineering for mining of coal or other diesel products.

As per screening practices, decrease drilling mud amount in unit, the shaker screensof drying shaker for sale is favorable to improve screening effect. When filled upto 80% to its capacity shale shaker performs as much as it could. So make sure that the shaker screen is big enough to conduct screening drilling mud which always think 2:1 rate for the length to width of the screen is the best design. Thus improving shaker screen will facilitate better working of shale shaker.

Size of shaker screens matters too! When a bigger size shaker screen is used in shale shaker it not only increases the vibration strength and amplitude but also improves the hitting force and shearing force reacted by shale screen to drilling mud and decreasing adhesive force between solid particles. Meanwhile, this measure is good at avoiding block of the screen to some extent, realizing drilling mud shearing and separation.

Basket angling mechanism-proper angling control the drilling mud flowing speed. Generally, big angle is faster than that of small angle. Although this practice is with big volume of shale shaker, it really does low efficiency. So, according to experience, it’s fine to keep cutting fluids speed <0.6m/S and 15 degrees for the screen.

Adding many layers screens to shale shaker- different particles are resent with different sizes thus to eliminate these multi-layer screen shale shaker can be used. Setting several layers of screen with bigger mesh form low to upper screens help to improve the shaking screen efficiency.

Proper cleansing and maintenance ways of the drying shaker for sale is important. If cleaned by brushes or sticks it can lead to damage of the screen. It is must to use proper cleansing solutions . Never use water with an oil or synthetic based mud. For maintenance of the shaker ensure the shaker components are in good order; rubber supports, tensioning mounts etc.

Drying Shaker Operation and Maintenance of Kosun

<h2> Drying Shaker </h2>

Drying Shaker is integral part of the drilling industry without which things would have been extremely different. If a drying shaker is under control and its work efficiency is not dependent on other factors or influenced by minor faults, it can largely affect the productivity of other equipments directly related to it.

1- In order to maintain a long-lasting life of Shale Shaker , you will need to make sure the parts like wedges, screw cap bolt, and springs on the shale shaker are installed correctly with no signs of fault.

2- Ensure the rubber parts of the Shale Shaker are installed properly and fully intact without any flaw or error. The screen of Shale Shaker is mostly rear and tear and will need constant replacement after normal usage. If wear down speed is faster than normal, check all the moving parts for proper functioning and security of screen properly.

3- Lubrication and constant maintenance of the device would help maintain life- long life of Shale Shaker.

4- If the drilling fluids flow out of the pore or damaged place, cuttings cannot be removed.

5- Any damaged screen should be repaired immediately.

6- Inspect cover on unused hopper discharge connection for leaks. Tighten connection and add silicone sealant to prevent leakage.

7- Tighten connection and add silicon sealant to provide any leakage into the device.

8- Check regularly for any accumulation of processed materials or any other obstruction in the interior.

9- Feeder blockage may be the cause of excessive splashing and uneven distribution onto the screen bed.

10- Wash off accumulated materials from the screen frame, interior of hopper and AWD angle adjustment components.

11- Check the operating environment of vibration isolation element and the stand parts of the screen, if damage or excessive fatigue should be removed immediately.

12- For those screens that have not been treated with pre tension, must do the 1h, 3h, and 8h screen tension test after installation.

Shale Shaker, Desander Close Relation

Shale Shaker

Shale shaker form the first stage barrier through which the drilling fluid or the mud passes. It is basically shale meaning clay, mud or silt, that has some specific structure which has been untouched since its deposition in ground; which is here separated. . The waste is processed first in the shale shaker before transferring it to the other equipment.

It is used to separate solids with diameter above 75µm. Different components of shale shaker are hopper, feeder, screen basket, vibrator and basket angling mechanism and vibrator. They are believed to be most vital in solid control system as their performance direct has impact on the successive equipment and also relates to the quality of processed fluids.

Desander is a devices along with desilter form pair of hydrocyclones that differentiate sand and silt from the drilling fluid in borehole or downhole. Desander is added below the mud taker following by shale shaker and degasser.

A desander is typically positioned next-to-last in the arrangement of solids control equipment, with a desander centrifuge as the subsequent processing unit. A drilling mud is added in its direction with an angle which is roughly at 90 degrees to it.

As the drilling mud is moved downwards in this cone shaped equipment solid particles are segregated from liquids ones by centrifugal force acting on these. This separated solid particles are allowed to continue move downward until is discarded from the hydrocyclones.

Desander are set to eliminate abrasive solids found in the drilling mud, which surpass the processing of H-I G Dryer Shaker. Desanders usually separate soild with diameter 45~74μm, and 15~44μm.

Different size of desanders and desilter are available which function similarly. They determine the size of particles the device removes from the mud system. Alike shale shaker desanders have no moving parts.

Kosun also provide balanced elliptical motion shaker , Drilling Fluids Dryer Shaker, Shale Shaker Screen , Drying Shaker ……

Kosun with more than 20 years experience in this aspect, welcome to contact us if you need.

Drying Shaker Provided by Kosun Manufacturer

Drying Shaker

Drying shaker is used to recover water-based or oil-based drilling fluid from chips to reduce the hydraulic ratio by 10% and significantly reduce waste disposal costs.

Drying Shaker are segments of penetrating gear utilized as a part of numerous ventures, for example, coal cleaning, mining, oil and gas boring. They are the principal period of a solids control framework on a penetrating apparatus, and are utilized to expel extensive solids (cuttings) from the boring liquid.

Drying shaker is considered, by the greater part of the penetrating business, to be the most critical gadget in the strong control framework as the execution of the progressive gear specifically identifies with the cleanliness of the treated boring liquid.

On the other side, A desander is generally organized by rearward over the traverse of action of solids control furnish, with a desander rotate as the subsequent dealing with unit.

Desanders are gone before by gas busters, gumbo launch gear (if used), shale shaker , mud cleaner (if used) and a vacuum degasser. Desanders are broadly utilized as a bit of oilfield penetrating. Hone has demonstrated that hydrocyclone desanders are budgetary and persuading gear.

On the inverse side, Hi-g drying shaker is sections of penetrating contraption utilized as a bit of different attempts, for example, coal cleaning, mining, oil and gas debilitating. They are the essential time of a solids control framework on an invading mechanical get together, and are utilized to evacuate expansive solids (cuttings) from the debilitating liquid.

Drying Shaker are considered, by the majority of the entering business, to be the most fundamental contraption in the strong control structure as the execution of the dynamic mechanical assembly especially identifies with the cleanliness of the treated depleting liquid.

Drying Shaker Provided by China Kosun Manufacturer with high quality and low price got well recognized by clients at home and abroad. Welcome to contact us!