In the construction process of the shield machine, the separation of slurry is an indispensable process. The separation efficiency also affects the tunneling efficiency of the shield machine. General slurry separation equipment includes shale shaker, rotary separators, centrifuges, filter presses, etc.

Centrifuge: The commonly used centrifuge is composed of two coaxial parts rotating around a static chamber. It is very effective for purifying bentonite mud, only keeping 6μm particles in the mud. Centrifuge is one of the very important solids control equipment.

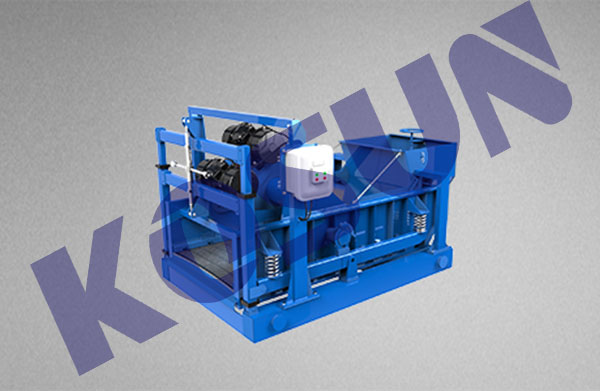

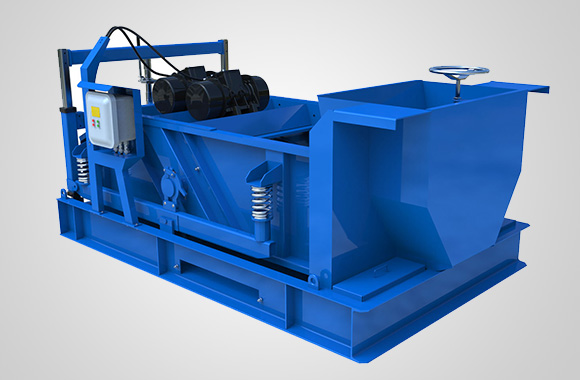

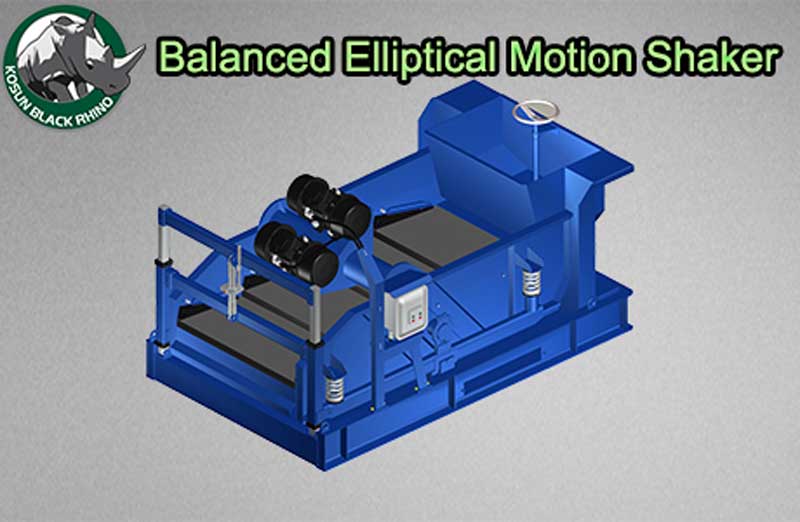

Shale shaker: For the separation of materials of different particle sizes and gradations, the mud Shale shaker is the most basic solids control equipment. The Shale shaker is composed of one or more sieve plates, and the sieve hole of each sieve plate is gradually reduced. Shale shaker are generally used for sieving coarse materials, with holes as small as 60μm.

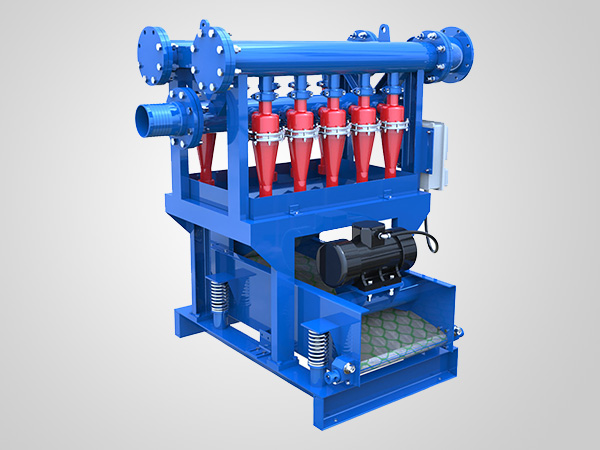

Rotary separator: The rotary separator is composed of a fixed cone. Its feed inlet is close to its shell. There is an upper overflow outlet at the top of the cone and a lower overflow outlet at the bottom. Larger speed is pumped into the rotating cone, causing it to produce a vortex, and the slurry enters the spiral in the cone. Large-sized and heavy-weight particles are separated by centrifugation at a certain speed, concentrated on the inner wall of the cone, and finally discharged through the bottom outlet; fine particles, retained in the muddy water, are discharged from the upper overflow through the spiral body. Rotary separators are widely used in surface separation stations. They can separate sand and sludge from waste mud water, and can even effectively separate 10μm particles.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com