Hi-G Drying Shaker is a kind of equipment of drilling waste management system, and is used to separate drilling fluid from cuttings treated by solids control equipment.

It features in two advantages:

1.It reduces total cuttings discharge amount, discharge cost and environmental pollution;

2.The recovered drilling fluid can be recycled, which reduces the cost of drilling fluid.

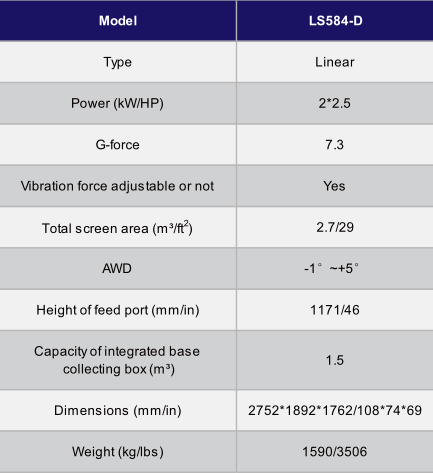

KOSUN LS584-D Hi-G Drying Shaker is a high frequency linear-motion vibrating screen machine, equipped with four screen panels and two vibrating motors, and offering a choice of manually adjusting screen frame angle while drilling (AWD). When LS584-D Hi-G Drying Shaker works, the screen frame angle can be adjusted from -1° to +5° by dint of its structural design innovation.

LS584-D Hi-G Drying Shaker can separate drilling fluid from cuttings efficiently. Fix vibrating motors onto the screen frame with a high-strength supporting seat, and position them on the screen box, and the positioning in this way can make vibrating motors directly exert G-forces on screens. The isolation mounts can protect the bedframe from vibration effect of the screen frame. Cuttings are fed into a hopper at the tail of screen box of LS584-D dryer by a conveying device.

Field-proven tensioning system is of stable performance and reliable structure. It takes less than two minutes for a person to install or remove one screen using special tools.

Kosun- China Solids Control Leader&Drilling Waste MangementExpert