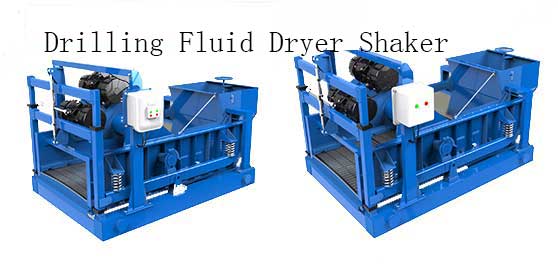

Balanced Elliptical Motion Shaker

Balanced elliptical motion shaker are particularly effective when drilling often encounter heavy, bulky solid parts of the wellbore.

Balanced elliptical motion shaker are particularly effective when drilling often encounter heavy, bulky solid parts of the wellbore.are considered core because they are the first line of defense in the solid control system. Shale shakers are parts of drilling waste equipment used in oil and gas drilling as well as coal cleaning and mining.

The Balanced elliptical motion shaker is of vital importance in the drilling process because if the beginning is flawed, then expect a poor end product.

Balanced elliptical motion shaker are the first and crucial equipment that ensure the process is initiated as flawlessly as possible.

As a separation equipment, the shale shaker separates harmful solids which are discharged into a separate holding tank while drilling mud is directed through the shaker screen . The role played by the shaker cannot be belittled. Shale shaker are important because

• They separate drilling mud from unwanted solids

• Discharge solids so they do not contaminate the drilling fluid

• Remove harmful solid particles from the drilling mud

• Provide rock samples for mud loggers to and analyze in order to determine the depth of penetration of the rock.

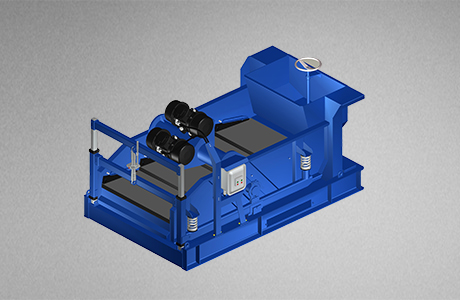

The shale shaker is composed of

• The Hopper which is also known as the base. This serves as a platform for the shaker and feeder.

• Feeder which is a collection pan for underflow

• Screen basket also known as screen bed, a significant part of the equipment which transfers the shaker’s vibrating intensity and regulates its vibrating motion.

• The basket angling mechanism has the capability to adjust its angle to allow different flow rates in order to optimize the use of the shaker bed.

• The vibrator is a motion equipment which vibrates to facilitate the transfer and regulation of vibrating motion by the shaker bed.

Acclaimed as the basic and important equipment in the first phase of drilling, it is important that users choose good quality shale shakers and maintain them as is required.