Mixing and Grouting Plants

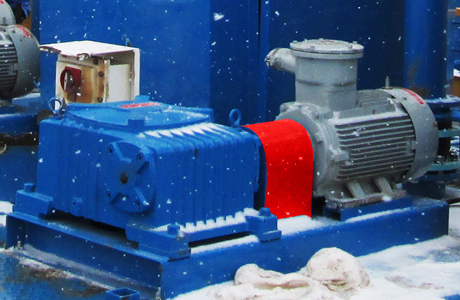

Mixing and Grouting Plants – KOSUN MA series of mud agitators are part of the drilling fluid solid control equipment, mainly used for mixing and grouting plants drilling mud to prevent the solid particles settling in the circulating tank.

The KOSUN MA Series Mud Mixer is part of the drilling fluid solid control unit and is used primarily for mixing and mixing drilling mud to prevent solid particles from depositing in the circulation tank and stabilizing the performance of the drilling fluid.

By the explosion-proof motor, reducer, motor base and blade composition. The motor reducer, reducer and impeller shaft are connected via a steel coupling. Impeller with four blades welded.

Mud Mixer Features and Benefits:

1.Helical gear reducer

2.Explosion-proof motor

3.Power range from 2.2 to 22KW

4. Capable of handling 20 ppg drilling fluid

5. Compact, quiet, smooth and easy to maintain

Kosun Solid Control as a professional manufacturer of soap control equipment, we have designed a large number of high quality products. In order to maintain mud homogeneity and solid suspensions, the slurry agitator can continuously and reliably mix the slurry.

The agitator stirs the mud so that the mud, sediment and sand pass through the solid control system without precipitating at the bottom of the tank. As a single turbine reducer, the product is compact, light weight, transmission balance, low noise, high transmission efficiency, strong stirring. Therefore, it is a reliable product in solid control systems.

Chinese manufacturer Kosun Solid Controls provides drilling mud mixing equipment for the rest of the world. We are exporters of drilling mud slurry mixers in India, Russia, and the Middle East. Our factories and companies are quality management system ISO 9001-2000 certification .

Kosun solid control operation of international oil and gas drilling mud separation system sales, service, manufacturing, distribution services. Chinese manufacturer’s drilling fluid slurry agitator. Your best mud agitator is used to drill mud circulation system.