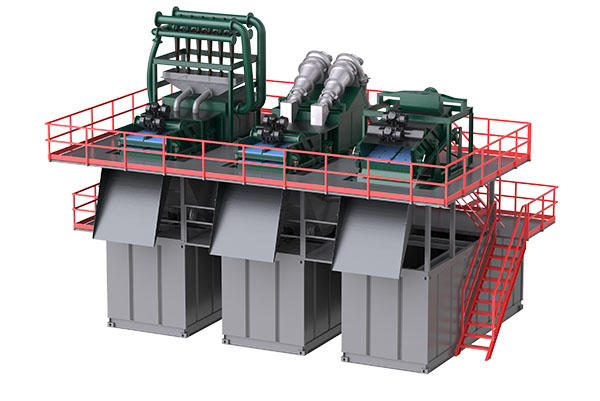

As the mud carrier, the mud tank is an indispensable part of the mud circulation system, which can in turn complete the weight of mud, slurry distribution, solid-liquid separation, degassing and other processes; The mud tank carries the mud circulation from the wellhead to the mud pump, and the solid phase particles in the mud are separated step by step through the corresponding solid control equipment on the tank, and the mud weight mixing system is deployed to meet the drilling process requirements.

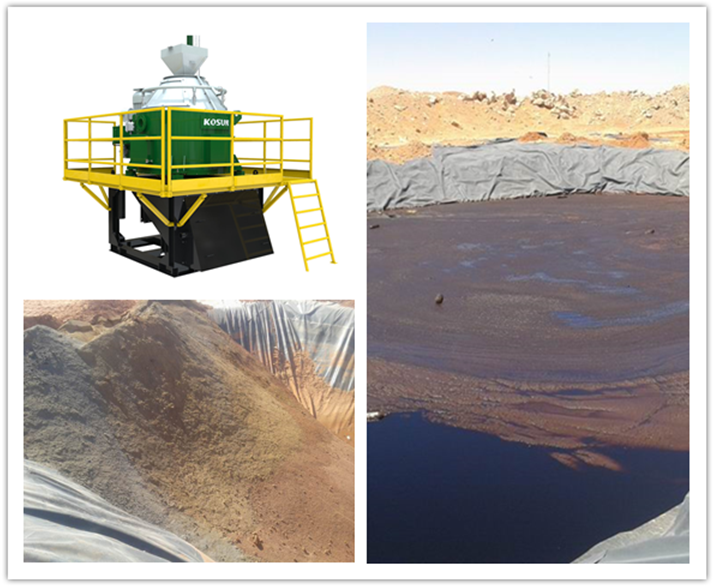

The degassing equipment on the mud tank can remove the harmful gas in the mud, so as to ensure the environmental requirements and mud weight of the work site; Mud tank adopts electrical centralized control. In polar regions, the tanks are equipped with heating and insulation systems.

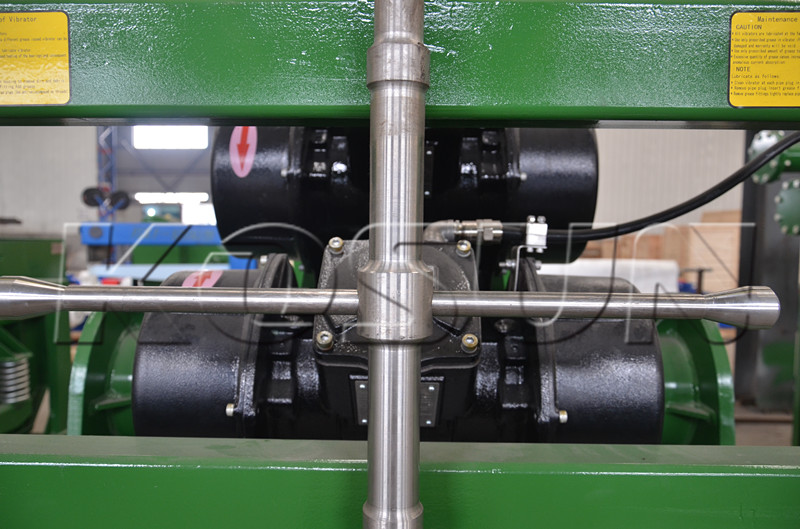

Mud tank on the supporting equipment generally: drilling fluid shale shaker, vacuum degasser, desander, desilter. Sand and mud removal machine, liquid and gas separator, mud agitator, sand pump, shear pump, centrifuge, electronic ignition device, mixing funnel, jet mixing device, mud gun, etc.

Mud tank as an indispensable equipment in the solid control system, the use of the need to pay attention to: do not let the mud tank sediment attached to the tank wall, reduce the capacity of the tank, is not conducive to cleaning.

Xi ‘an KOSUN manufacturing series mud tank is mostly square tank, the base of i-steel as the main beam plus other profiles, on the basis of meeting its strength requirements made of skid-mounted structure.