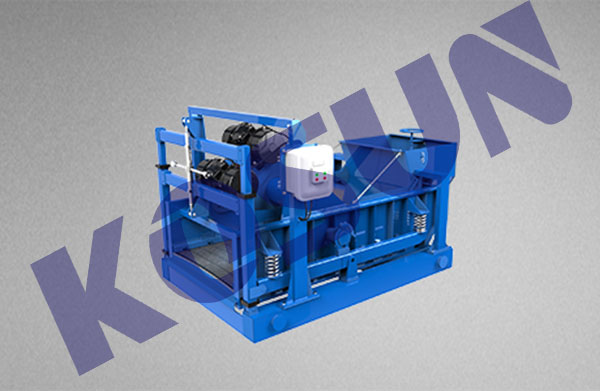

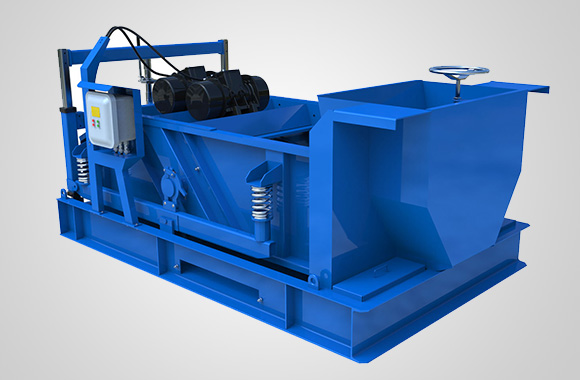

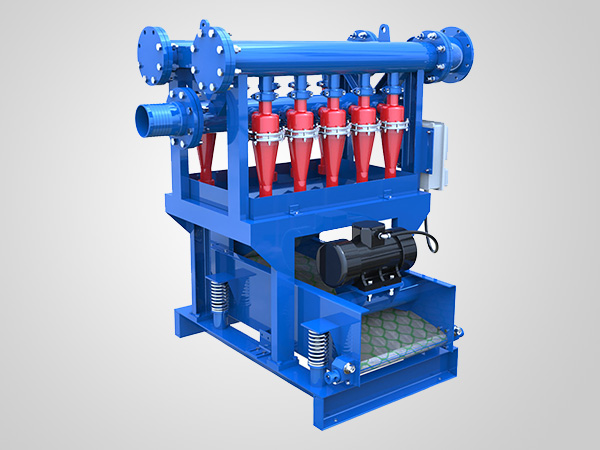

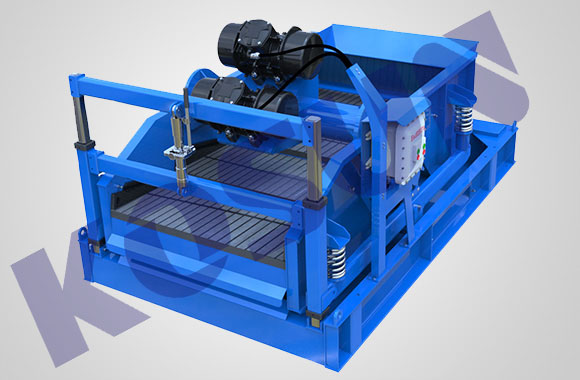

In oil drilling mud treatment system, the drilling fluid that returns from the well first passes through a linear motion shale shaker and then into other solids control equipment. Shale Shaker is a filtering mechanical separation equipment. It features the first and fastest separation of solids in the solid phase in an entire solid-phase clean-up system, as well as an economical and efficient separation plant.

Compared with other solid control equipment, KOSUN linear motion shale shaker has obvious advantages when dealing with large displacement drilling fluid, powerful excitation force output by the drilling fluid vibrating screen, rapid removal of a large amount of solid phase through efficient drilling fluid vibration trajectory. Linear motion shale shaker can effectively remove larger particles in the drilling fluid.

Factors that determine the efficiency of linear motion shale shaker:

(1) Vibrating Form – There are three types of vibrating screen motions, circular, elliptical and linear. Each form of motion is generated by the difference in the center of gravity of the system. Linear movement is the oscillator on the top of the system before the center of gravity, the screen frame to produce linear motion, thus clearing the solid phase. Straight-line motion has a constant cut-off speed of the cuttings, which can be either flat or slightly inclined.

(2) Amplitude and frequency – The sieve capacity of the shaker depends on three parameters: amplitude or stroke, vibrational mode and pendulum rotation speed. Most circular motion shakers have 4-6 times the acceleration of g, most of the linear motion of the shaker has 3-4 times the acceleration of g.

(3) Slope and mesh number of screen cloth – The screen cloth moves the whole drilling fluid through vibration to separate the solid phase. Elliptical shakers are usually placed at different slopes. The purpose is to properly discharge drill cuttings. The screen surface can be either a bevel or a few bevels.(Editor:Kosun Lily.Wang)

Kosun- China Solids Control Leader&Drilling Waste Management Expert

Tel.: +86 29 87304914

Email: sales2@adkosun.com

Contact person: Lily Wang

Online consulting: