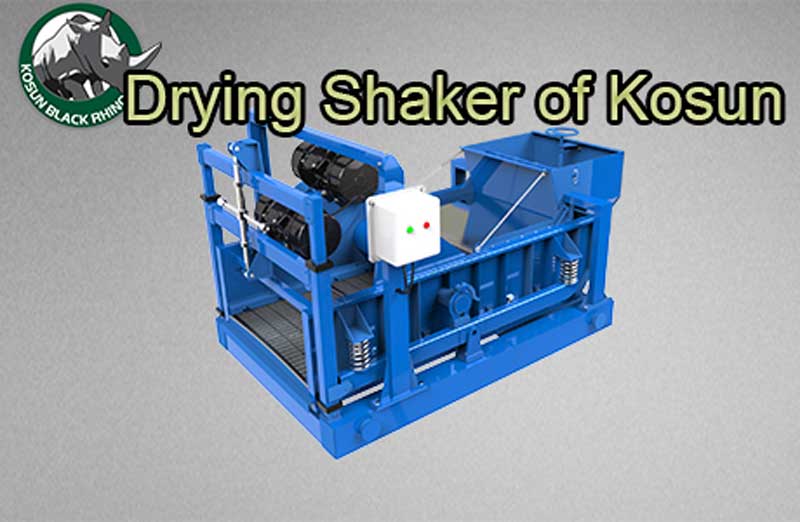

Drying Shaker

Drying Shaker is one of the solid control equipment in drilling waste purification system and Kosun with more than 20 years experience in this aspects.

Drying shaker of maintenance is straightforward, while there are a considerable measure of basic disappointments additionally, we have to comprehend the normal deficiencies of boring liquid shaker and how to manage. The following are some common problems faced concerning the drying shaker:

The vibration engine pivot turn out to be gradually, and there is a heading warming:

This demonstrates the typical upkeep of the shale shaker was not done well, and the bearing is shy of greasing up oil, if the oil is recently included the reason will be oil quality issues or get too full, second rate oil make the bearing square so oil quality is very essential.

The poor screening nature of penetrating drying shaker:

This issues may for the most part brought on by the mis operation, it might be the shaker screen work blockage, fine grain size and increment of water substance in the strainer material, the sifter material layer is too thick, sustaining imbalance, etc. May both sides of the screen is not tight, in the event that it is an offbeat shaft vibration may the belt is too free, a time of invert revolution can be taken after the mechanical preparing is finished keeping in mind the end goal to enhance the nature of screening.

Shaft break of shale shaker box:

In the event that the screen box has been because of absence of inflexibility, flat level did not recognize, will bring about the shaft crack, on the off chance that it still in operation will likewise make the material stream peculiarities. There likewise might be uncalled for operation, that is the imbalanced sustaining is additionally one reason.

The shale shaker can’t begin or plentiful is too little:

Ought to check whether the aggregation of oil on the electrical machine is excessively, if so we ought to expel stores on the vibrating screen.

Drying Shaker for Sale by Manufacturer Kosun serving clients at home and abroad and been praised good in performance.