Solid control system is also called drilling fluids purification system, primarily applied for solids control and solid-fluid separation in drilling fluids so that the drilling mud might be recycled. Consisted of 3-7 module composite tanks and configured with 4 phases of purification equipment, it is fit for 2000-7000 meter oil drilling processes. The whole system is innovative with the bottoms of its purification tanks made to be conical and its edges equipped with mud agitating system to prevent solids from depositing. Besides, its tanks and bins may be comparted or united depending on the demands of drilling processes. Each of them is connected to another via pipe network in which the valves at the bottom of suction pipes are flexible while being opened, but can turn to be a good seal when closed.

The Component of the Solid Control System:

The first main equipment for solid control system should be the vacuum degasser,We could analytics from the function of vacuum degasser. Generally speaking, horizontal vacuum degasser will be used to separate the gas from the drilling solids. What’s the reason to do like that? Because we should do everything to prevent any dangerous elements in oil & gas drilling fields. That’s why we should put the vacuum degasser as the first role.

The second one should be mud cleaner. KOSUN MD Series Mud Cleaner is the second stage separation equipment for drilling fluids, which deals with the mud being treated by the first grade separation equipment. The barite will be recovered and cuttings which are bigger than barite will be removed. Then the barite in the underflow will flow into circulation tanks through the screens when the weighted mud passes while the particles that are bigger than mesh will be removed.

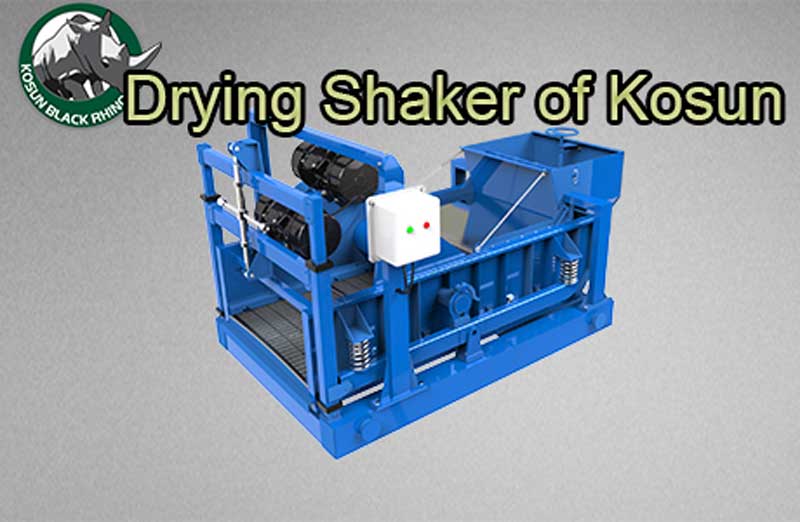

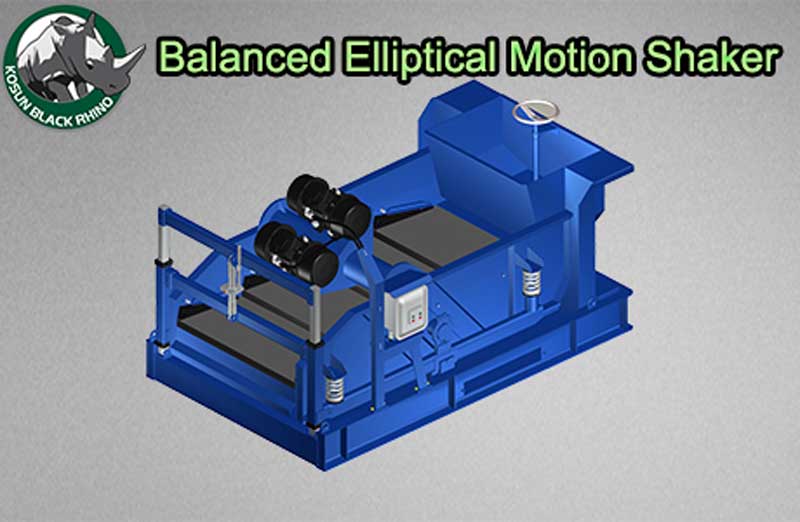

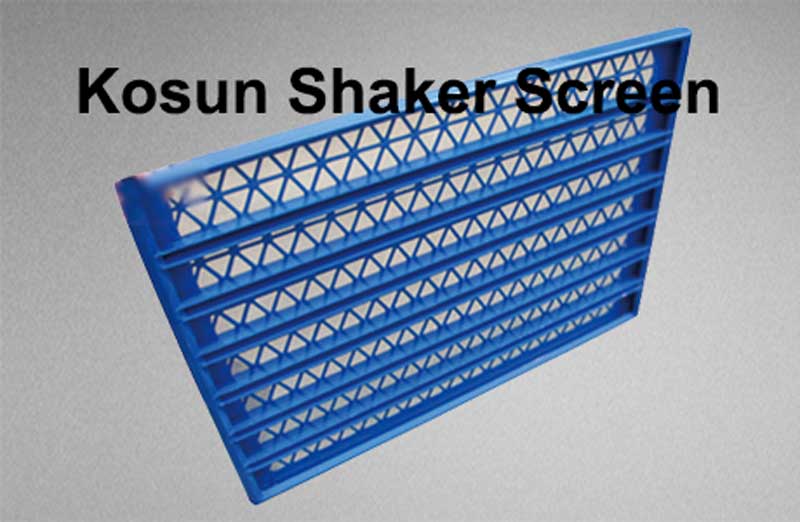

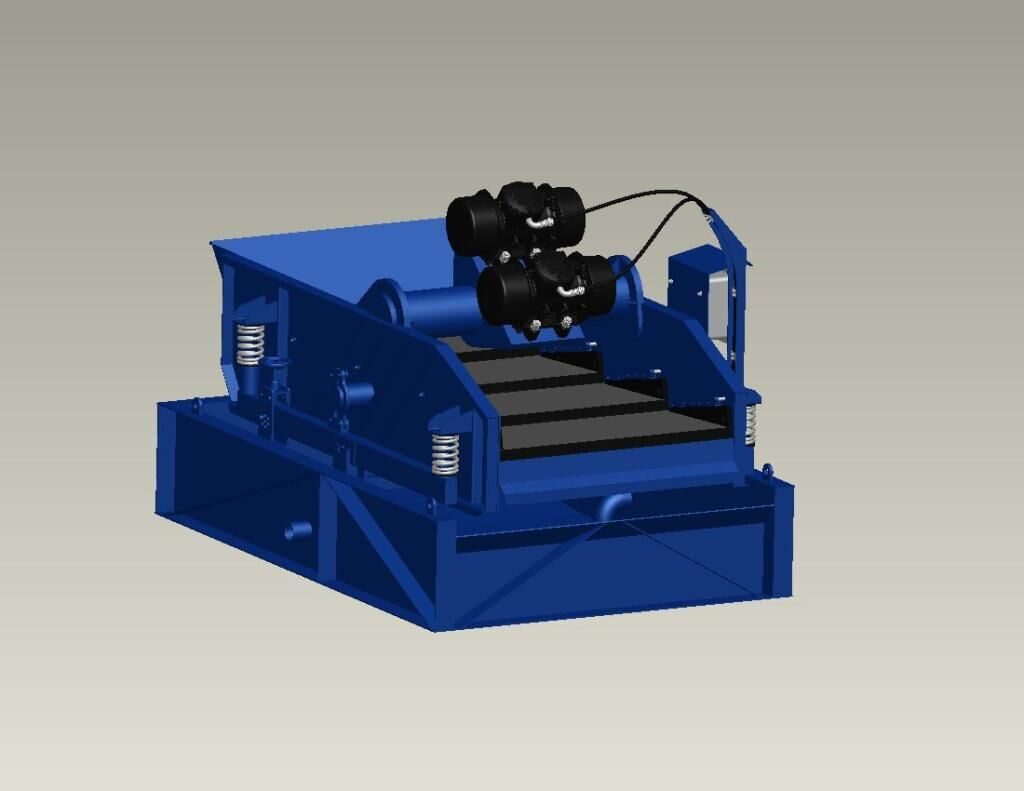

The third equipment, we think it should be shale shaker (with necessary steel frame shaker screen). Actually, after the drilling solids have been transported and fed into vacuum degasser and mud cleaner, the third step is going with shale shaker. Commonly, we still need to be transported the solids onto the shale shaker, or we could say onto the surface of shaker screen. The equipment of transporting we should use is centrifugal sand pump or screw pump; and we may use shear pump to cut the drilling solids into small one if they are in big size. With the different design of the shaker screen’s mesh, we could get the drilling solids separated in different sizes.

The fourth equipment should be the decanter centrifuge. KOSUN DC Series Decanter Centrifuge is used to separate suspended solids ≥2μm in diameter and treat the drilling mud and fluids. It is especially effective when used in oilfield service industry, industrial service industry and especially in environmentally sensitive areas. This type of centrifuge is high in recovery rate, effective in solids control and remarkable in the reduction of cost spent on drilling mud resupplying and management. It is a very sophisticated dynamic balancing machine, able to operate stably with the whirling speed ranging from 0 to 3900 and generate centrifugal force of 3000G. In solid control system, decanter centrifuge has been popularly used, which is also the popular one for drilling waste management. In this step, we could not only get the result of separating, but also we could separate the oil from the drilling solids, even if the oil is just a little part.

Of course, the whole equipment must be mounted on the top of drilling mud tank, which is a kind of basic equipment for both solid control system and drilling waste management (vertical cutting dryer is the core equipment for this system), but it is a kind of powerful equipment.

Kosun- Solid Control System Company