Hi-G Drying Shaker is a kind of equipment of drilling waste management system, and is used to separate drilling fluid from cuttings treated by solids control equipment.

It features in two advantages:

1.It reduces total cuttings discharge amount, discharge cost and environmental pollution;

2.The recovered drilling fluid can be recycled, which reduces the cost of drilling fluid.

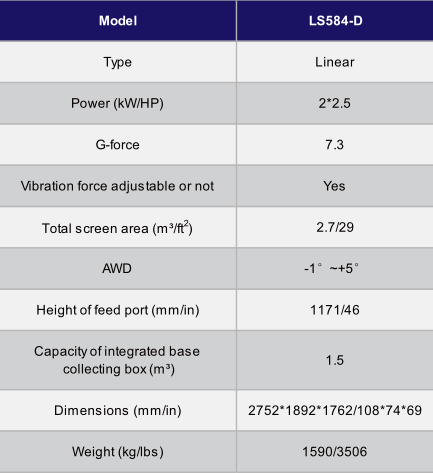

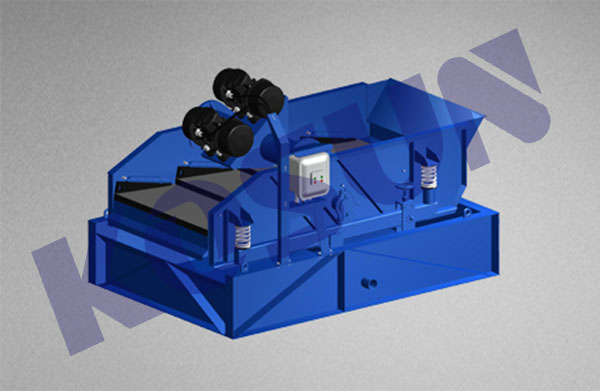

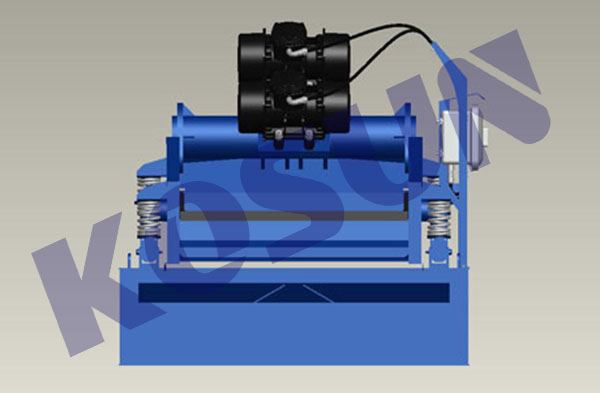

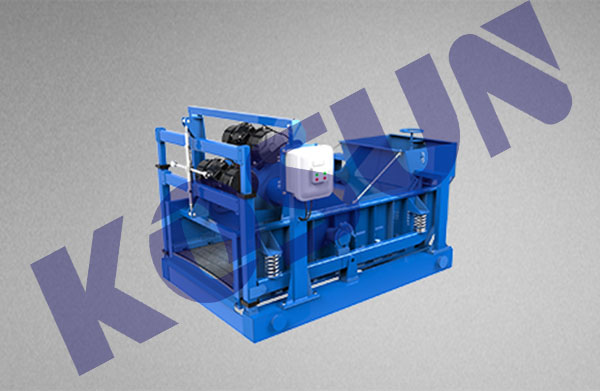

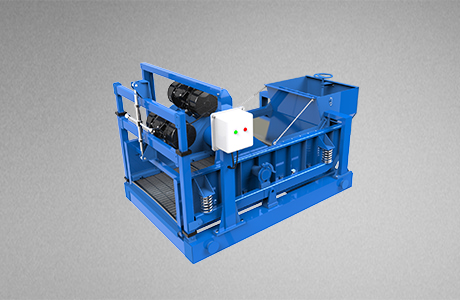

KOSUN LS584-D Hi-G Drying Shaker is a high frequency linear-motion vibrating screen machine, equipped with four screen panels and two vibrating motors, and offering a choice of manually adjusting screen frame angle while drilling (AWD). When LS584-D Hi-G Drying Shaker works, the screen frame angle can be adjusted from -1° to +5° by dint of its structural design innovation.

LS584-D Hi-G Drying Shaker can separate drilling fluid from cuttings efficiently. Fix vibrating motors onto the screen frame with a high-strength supporting seat, and position them on the screen box, and the positioning in this way can make vibrating motors directly exert G-forces on screens. The isolation mounts can protect the bedframe from vibration effect of the screen frame. Cuttings are fed into a hopper at the tail of screen box of LS584-D dryer by a conveying device.

Field-proven tensioning system is of stable performance and reliable structure. It takes less than two minutes for a person to install or remove one screen using special tools.

Kosun- China Solids Control Leader&Drilling Waste MangementExpert

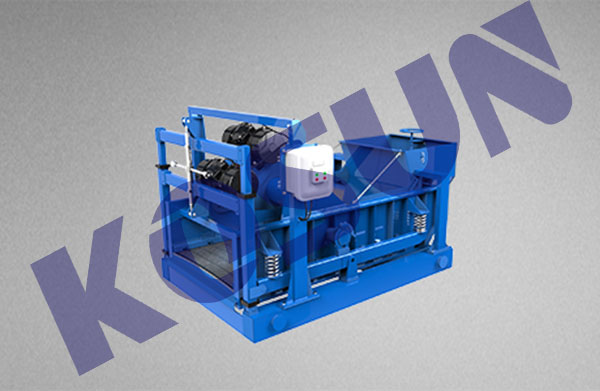

Double Deck Drilling Fluids Shale Shaker

Do you know the Double Deck Drilling Fluids Shale Shaker ? Now Let’s talk the avantages and disadvantage of it.

Advantages of Double Deck Drilling Fluids Shale Shaker:

- For the same API size and the same area bottom shale shaker screen,double deck shale shaker can treat a bigger capacity. The wide-meshed shaker screen on top deck can separate most big size solids before the mud enter into the bottom deck. It greatly reduce the load of bottom shale shaker screen.

- For the same API size and the same screen area shaker screen,double deck shale shaker can separate the drilling mud or drilling cuttings more dryer. As there are 2 times shale shaker separation.

Disadvantages of Double Deck Drilling Fluids Shale Shaker:

The double deck shale shaker have advantages of bigger advantage and dryer separation result, but it has some difficult to change shale shaker screen. And the cost of replacement shaker screen also higher, as there are 5 each shaker screen for a shale shaker.

Shale shaker for solids control are devices that remove drill cuttings from the drilling fluid while circulating and drilling. There are many different designs and research into the best design is constantly ongoing since solids control is vital in keeping down costs associated with the drilling fluid. The basic design consists of large, flat sheets of wire mesh screens or sieves of various mesh sizes that shakes or vibrates the drill cuttings, commonly shale shaker, across and off of the screens as the drilling fluid flows through them and back into the drilling fluids processing system, often called a mud system. This separates the drill cuttings, often called solids, from the drilling fluid so that it can be recirculated back down the well bore.

In oilfield industry, linear motion shale shaker are widely used for drilling mud solids control of oil gas well drilling for rig.

Kosun- China Solids Control Leader&Drilling Waste MangementExpert

Features and Advantages of Hi-G dryer shaker

KOSUN Hi-G dryer shaker is used to recover the mud from drilling cuttings,so as to reduce the liquid/oil content drilling cuttings to as low as about 10%(w/w) and recover part of the drilling mud,so that the drilling cost can be reduced and the drilling waste volume can be cut down,for the purpose of reducing environmental pollution.The Hi-G dryer shaker suitable for both of WBM and OBM.

Features and Advantages of Hi-G dryer shaker:

- G-force linear motion shaker with up to 8G vibrational force;

- Make drilling cuttings more dryer;

- Weir type feed box is more applicable to on-site process;

- Fast drilling cuttings conveying speed and high handling capacity;

- Screen frame tilt angle can be adjusted from -1° to 5°;

- Rapid screen tensioning system ensures easy screen replacement;

- Hi-speed conveyance.

- Able to process heavier cutting loads.

- Shaker feeder can be weir type and header box.

- Hoop-strip screens can be PMD and PWP screen.

KOSUN Hi-G dryer shaker is used to recover cuttings from water-based or oil-based drilling fluids so as to lower the hydraulic proportion than 10% and significantly reduce the cost on waste discharge. It is proved to be particularly effective in recovering the oil-based mud cuttings.

Based on a combination of innovative design and highly advanced technology, KOSUN dryer shaker allow high throughput capacities to be achieved in a compact machine design. These features facilitate the layout and design of the complete dryer shaker for mud system. Shaker dimensions can be significantly reduced, ensuring low investment costs and saving space for other oil tools, especially for offshore drilling plant.

Kosun- China Solids Control Leader&Drilling Waste Mangemnet Expert

Advantages of KOSUN LS and ES Shale Shakers

Based on a combination of innovative design and highly advanced technology, KOSUN shale shakers allow high throughput capacities to be achieved in a compact machine design. These features facilitate the layout and design of the complete shale shaker for mud system. Shaker dimensions can be significantly reduced, ensuring low investment costs and saving space for other oil tools, especially for offshore drilling plant.

KOSUN S™ series Shale Shakers family consist of linear motion (LS) shale shakers and Balanced Elliptical Motion (ES) Shale Shakers.

KOSUN LS Shale Shakers are ideal for high-capacity processing and the compact and easy-to-service design makes them a perfect choice for fast conveyance and heavy loading in tough drilling conditions. When drilling top-hole sections or while heavy-volume solids are encountered, in these intervals, shakers are required to generate high G-forces to effectively move high-capacity drilled solids across the screens.

KOSUN ES Shale Shakers are the best choice for max retention time and frequency for highly need of dryer drilled cuttings in light-loading drilling conditions. The unique balanced elliptical basket and easy-to-service design makes them a wonderful choice for reducing solids control operation cost. When faced with gentle light-loading drilling fluids, the ES shakers are required to reduce G-forces and maintain longer screen residence time, this results in drier solids,better drilling fluid recovery, longer screen life and reduced operating costs.

Advantages of LS Shale Shakers and ES Shale Shakers:

-High and constant capacity

-Low space requirement

-High machine availability

-Long lifetime

-Reduce NPT(non-productive time)

-Easy replacement of wear and spare parts through

-Hydraulic opening device

-Broad range of applications

-High reduction ratio

-Lower drilling fluids cost

KOSUN shale shakers LS series and ES series are mostly used for the primary, scalping, fine separating and drying stage of soft to medium-hard drilled solids in various drilling fluids, for both oil-based and water based.The KOSUN shale shakers LS series and ES series have a wide field of use as they can easily be matched to changes in production through the proper selection of OPERATION MODE.

Kosun- China Solids Control Leader&Drilling Waste Mangemnet Expert

Drying Shaker, dryer Shaker for Sale

KOSUN Drying Shaker,dryer Shaker is used to recover the mud from drilling cuttings,so as to reduce the liquid/oil content drilling cuttings to as low as about 10%(w/w) and recover part of the drilling mud,so that the drilling cost can be reduced and the drilling waste volume can be cut down,for the purpose of reducing environmental pollution.The Hi-G Drying Shaker,dryer Shaker suitable for both of WBM and OBM.

Features of Drying Shaker, dryer Shaker:

- High G-force vibration intensity (adjustable as per working conditions);

- Make drilling cuttings more dryer;

- Weir type feed box is more applicable to on-site process;

- Fast drilling cuttings conveying speed and high handling capacity;

- Screen frame tilt angle can be adjusted from -1° to 5°;

- Rapid screen tensioning system ensures easy screen replacement.

Advantages of Drying Shaker, dryer Shaker:

-Low maintenance dryer reduces operational costs.

-Wedgelok system allows for quick screen changes.

-Centrifugal pump and spray bar unit built into the fluid recovery tank.

-Single shaker unit is mounted in a four sided shale bin.

-Dual Shaker unit is skid mounted for easy, cost effective transport.

-Includes an auto-pump feature to prevent potential spills.

KOSUN’s solids control and waste management solutions can provide a closed-loop, zero discharge system to meet all your needs when it comes to location, budget, safety and environmental requirements. KOSUN offers premium linear motion drying shaker to ensure a fast and efficient turnaround time on your fluid recovery process. The linear motion drying shakers are a multi-functional drilling fluid cleaner that is equipped to handle varying drilling fluid viscosities and remove solids from your drilling fluid. It is designed with a high g-force and pretensioned screens to optimize the flow of drilling fluids. It provides a cleaner reclaimed fluid that can be utilized back into the drilling fluid program.

Kosun- Solids Control Company/ Drilling Waste Management Company

How to mark shaker screen size?

So many different shale shaker screen, how to verify them? How to mark shaker screen size? For almost screen, we’ll mark the shale shaker screen sizes on the tag or label. On labels, there are screen dimension, API size or mesh sizes.

Tags of shale shaker screen can be printed on special tag paper, on PP sticker, on metal plate, and so on. No matter which type label we use, the necessary information should be indicated clearl.According to API RP13C code, the screen sticker should indicate API size, cut point under D100 cut point regulation, the mesh size or model number of manufacturer, the screen origin, manufacturer name, and so on.

Shaker screen dimension, usually means the overall size of screen panel. If the screen is framed one, dimension include length, width, height or thickness. If the screen is hook strip, dimension means the length, width, and hook height or hook size.Besides screen overall size, there are detail size on screen panels. Such as holes shape and size. The screen cloth mesh size. Effective screen area, the non blanked area, and so on

The popular shale shaker screen sizes including 700x1050mm, 630x1250mm, 585x1165mm, 710x1250mm, and so on. Mesh sizes for oilfield solids control shaker are usually from API 40-API325.

KOSUN Shale Shaker Screen is wear part of the shale shaker, mainly classified into soft sieve screen, sieve plate type screen,and frame plate type screen.Product characteristics are wear resistance, wearability, rating of temperature, low cost, easy disassembly, conductivity ( powder ) liquid, good trapping ( dreg ) effect, etc.

Kosun- Solids Control Company/ Drilling Waste Management Company

Drilling Fluids Shale Shakers- KOSUN

As the 1st part of mud utilization,drilling fluids shale shakers are often expeditiously have an effect on the improvement method. KOSUN shale shakers with shear pump is animated by G force, which might be adjusted accruing to the various scenario. In general, the GHB force are often additional to seven.4G. So, shale shaker screen will change the force in accordance with their totally different things.

KOSUN field shale shakers is nice at the significant solid hundreds and high process capability. Every time, the device permits bearing lots of solids. With an explicit amount, KOSUN drilling fluids shale shakers might have a decent performance to separate and clean. Besides, mud gun options the only deck. The AWD angle is allowed to be adjusted from -1°to 5°. So, mud gun might create a decent adjustment thus on transfer, separate and clean mud.

KOSUN shale shakers for lubricator system has not solely technical options, however additionally some advantages. for instance, the decanter centrifuge instrumentality has low energy consumption, Drilling Waste Management high production and automatic performance. decanter centrifuge is most significantly, field shale shakers offered by KOSUN shear pump options straightforward structure, however DWM Solids Control’s excellent compact style, that is definitely to be maintained. Contact us for additional data concerning sedimentary rock shaker.

As a necessary part of solids management instrumentality, sedimentary rock shaker plays a very important role within the field.It’s the primary stage of solids control system. without doubt, lubricator shale shaker screen is crucial. KOSUN solid control system has reliable field drilling shale shaker screen, that has many distinctive options in Dwm control.

Kosun- Solids Control Company/ Drilling Waste Management Company

Types of Drilling Fluids Shale Shaker

Types of Drilling Fluids Shale Shaker:

1) Linear motion shale shaker. It is the most common shaker model for oil and gas drilling solids control system;

2) Balanced elliptical motion shale shaker. It is not recommended for oil and gas drilling since the flow capacity is big. If the mud flow is not equal, the motion of shaker will be changed. And performance will not be good. Mostly, professional users prefer linear motion for wide application.

Functions of Solids Control Equipment-Shale Shaker

Shale shaker is the first stage separation equipment for oilfield drilling mud cleaning system. It utilizes vibrating motor to generate vibrating strength. The vibrating strength drives the drilling mud to go through the shale shaker. When the drilling mud goes through the shale shaker screen, clean mud will filter into mud tank. Not allowable bigger solids will pass the screen surface and be discharged.

Separation Size of Solids Control Equipment – Shale Shaker

The separation size of shale shaker depends on shale shaker screen size. We call it API size or mesh size. The API defers from API 20 to API 325 per API RP13 standard.Through changing different API size shale shaker screen, the shale shaker can separate solids size min. above 40μm (at API 325 shaker screen).If you do not need to separate so fine solids, you can choose more fine shaker screen, like 800μm.The common screen API size for shale shaker is API60, API80, API100, API140, API160. Customer can choose the suitable size per drilling mud condition.

AWD Angle Adjustment System for KOSUN Shale Shaker

KOSUN AWD angle adjustment system for shale shaker is a patented design. It is synchronized change for both sides. You can adjust from any side, the angle change is the same for both sides.

KOSUN has options for AWD angle adjustment: Left side of the drilling shale shaker is a small motor for automatic control. And there is control for the small motor on shale shaker control panel. Right side of the shaker utilizes tools for angle adjustment. KOSUN will offer tools together with the shaker. Customer can choose any way to change the angle.

Kosun- Solids Control Company/ Drilling Waste Management Company

Drilling Waste Management Equipments top Supplier

Drilling waste management equipments are used for process drilling waste from solids control system. The main equipments will including high g dryer shaker, vertical cuttings dryer, decanter centrifuge, screw pump, screw conveyor, solidification system, chemical mixing unit, etc.Kosun Solids Control is one of the top suppliers of drilling waste management equipments in China. The equipments choose and layout will be depending on drilling waste and client requirement. Amount all drilling waste management equipments, hi g dryer shaker, vertical cuttings dryer and decanter centrifuge are the key equipments.

Drilling Waste Management Equipments Supplier– Kosun Solids Control

Kosun Solids Control is a manufacturer for drilling waste management equipments, solids control equipments and oil sludge treatment system in China. Kosun manufacture the top technology of Hi G dryer shaker, decanter centrifuge and vertical cuttings dryer. Other than equipments, Kosun hold an shaker screen factory in xi’an city to supply a series of replace shaker screen with various type design. The shaker screen build 3 layer and super thin mesh for better screen performance.

Drilling Waste Management Equipments – Vertical Cuttings Dryer

Vertical cuttings dryer is design like a vertical centrifuge with 900RPM speed to dry solids and separate fluids out through a screen basket. It will be used for oil base mud drilling cuttings to dry solids with oil content bellow 5 percent. For the screen basket, the mesh size can be customized from 0.25 to 1.0mm.

Drilling Waste Management Equipments – Hi G Dryer Shaker

Hi G dryer shaker is design to dry solids by a high G force to separate solids though shaker screen. It is used for waster base mud drilling cuttings mainly. The shaker screen mesh size will be depending on drilling waste conditions. The G force will be fixed on 8.0 – 8.5G to reach an application.

Kosun- Solid Control System Company

Solids Control Equipment Decanter Centrifuge for sale by KOSUN

KOSUN LW series decanter centrifuge is used in separating suspension of solid phase with particle diameter d≥2μm for drilling mud and fluids handling. Ruggedly built for oilfield and industrial services, it is especially effective in environmentally sensitive areas. It delivers high fluid-recovery rates and efficient solids control to significantly reduce the costs of makeup fluids and disposal. The decanter centrifuge is precision –balanced for smooth operation over long periods at speeds of 0 to 3900 RPM, generating centrifugal forces up to 3000G’s.

Decanter centrifuge for sale by KOSUN

Decanter centrifuge for sale by KOSUN consists of a cylindrical rotor, a casing, an electric motor, and three lines for material to travel. The gas centrifuge is designed with a casing that completely encloses the centrifuge. The drilling mud decanter centrifuges can separate fine particles well, for separating 5~7μm particles in drilling mud, usually use medium speed decanter centrifuge, for less then 2μm, usually use high speed decanter centrifuges.

KOSUN decanter centrifuge features:

- Innovative design includes longer bowl for increased retention time, resulting in drier solids and finer cut points

- Big bowl Big Volume, high G force available

- Stainless steel bowl, scroll, compartment and cover resist corrosion and provide long service life.

- Tungsten carbide scroll points with wide spacing flights at tapered end create a finer layer of conveyed solids for consistent, uniform separation and maximum solids control efficiency.

- German FAG or Sweden SKF brand bearings

- Electrical Components: SIEMENS/Schneider ATEX or IEC Ex for option.

- Screw pump & centrifugal pump feeding pump option available to meet different application.

As a solids control equipment decanter centrifuge manufacturer, KOSUN supply other solids control equipment for sale, including shale shaker, shale shaker screen, desander, desilter, vacuum degasser,decanter centrifuge , centrifugal pump, submersible slurry pump, shear pump, mud agitator, mud gun, drilling fluid mud cleaner, decanter centrifuge, mud tank, diesel tank, water tank, complete solids control system, etc.

Kosun- Solid Control System Company